Product Meta Description

Mirrordick AD45 Mirror Surface EDM machine delivers exceptional precision machining for mold & die industries. Featuring Windows CNC, auto electrode change, and 3D inspection, it boosts productivity and achieves flawless mirror finishes. Ideal for automotive, medical, and consumer electronics manufacturing.

High precision mirror EDM machine

Windows control system(multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Spark oil constant temperature device

Special option

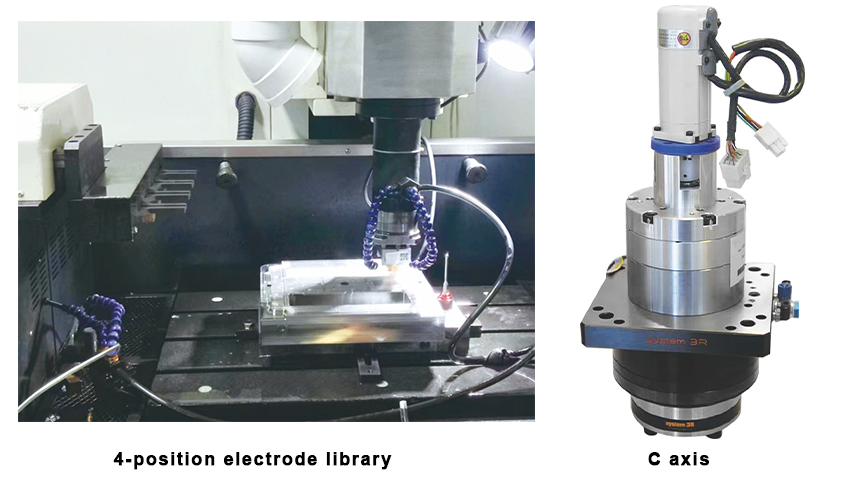

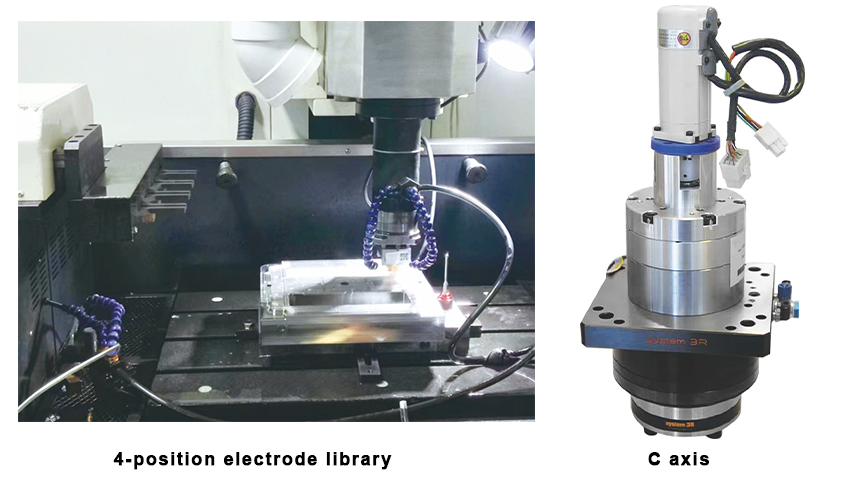

C axis

4-position ATC electrode library

Stabilizer

Quick Chuck

Parameter

Product Description

Unlock Superior Surface Finishes with Mirrordick AD45 Precision EDM

Mirrordick, a leading high-tech enterprise specializing in the R&D and production of precision Mirror EDM machines, proudly presents the AD45 model. Engineered for excellence, this machine embodies our core philosophy of "Quality First, Service Foremost."

The AD45 is designed to meet the rigorous demands of modern manufacturing, where superior surface quality and extreme accuracy are non-negotiable. Based in Shenzhen with our production facility in Heyuan, Mirrordick combines innovative technology with practical user feedback to deliver a machine that not only meets but exceeds expectations. Our global presence, including customer experience centers in Vietnam and India, ensures we understand and serve international markets effectively.

The AD45 Spark Machine is your ultimate solution for achieving perfect mirror finishes on complex molds, dies, and components, significantly reducing polishing time and costs while enhancing overall production efficiency.

Key Features

Windows-Based CNC System: User-friendly interface supports network transmission and open automation data ports for seamless integration into smart factories and Industry 4.0 environments.

Multi-Station ATC (Automatic Tool Changer): Equipped with an automatic electrode changer library, it enables uninterrupted, lights-out operation, dramatically reducing manual intervention and cycle times.

Advanced 3D On-Machine Inspection: Allows for precise measurement and calibration of electrodes and workpieces directly on the machine, ensuring utmost accuracy and eliminating secondary setup errors.

Auto-Elevation Die-Sinking Oil Tank: Enhances operational convenience and safety, facilitating easier setup and maintenance.

Patented Core Technology: Incorporates award-winning innovations that ensure stable machining, exceptional surface finish quality (reaching true mirror surface), and enhanced durability.

Rigid Machine Structure: Built with high-quality materials for outstanding stability and precision, even during long, complex machining cycles.

Key Benefits

Dramatically Increased Productivity: Automation features like ATC and intelligent programming minimize idle time, allowing you to produce more parts faster.

Unmatched Precision and Quality: Achieve consistent, high-quality mirror finishes (Ra ≤ 0.1µm) that eliminate or greatly reduce the need for manual polishing.

Significant Cost Reduction: Save on labor costs through automation and on secondary processing costs through superior surface finish.

Future-Proof Automation: Ready for automated production lines with open data interfaces and smart factory compatibility.

Lifetime Support & Peace of Mind: Backed by Mirrordick commitment to "lifetime free system upgrades" and "unlimited free machining process support," ensuring your investment is protected long-term.

Global Service Network: Supported by our experience centers and partners worldwide, ensuring prompt technical support and service.

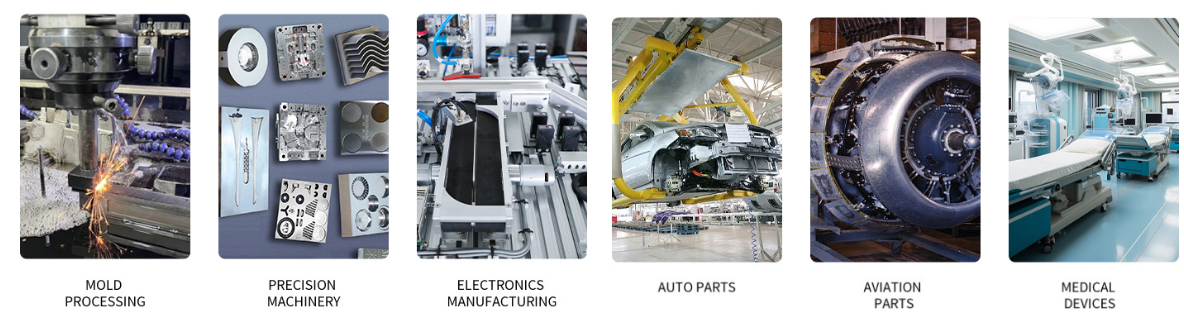

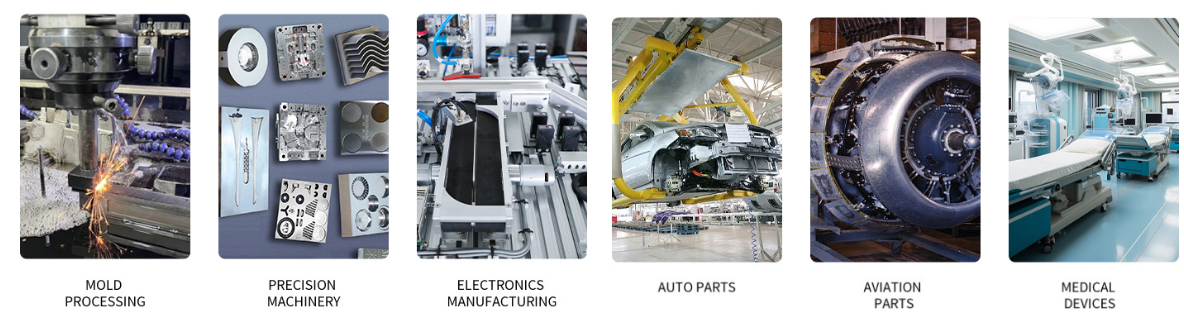

Application Industries

The AD45 mirror surface EDM Machine is indispensable in industries requiring the highest levels of precision and surface finish:

Injection Mold & Die Making: For cavities, cores, and intricate details in plastic molds.

Precision Stamping Dies: For delicate and complex stamping die components.

Medical Device Manufacturing: For surgical tools, implants, and micro-components requiring biocompatible surfaces.

Automotive Industry: For manufacturing critical components like gear molds, sensor parts, and connectors.

Consumer Electronics: For machining molds of smartphone casings, glasses, and other aesthetic parts.

Micro-Machining: For producing small, intricate parts for aerospace and optics.

FAQ

Q: What surface finish can the AD45 EDM machine achieve?

A: The AD45 is specifically engineered to achieve true mirror surface finishes, typically measuring Ra ≤ 0.1µm or better under optimal conditions.

Q: Does it support unmanned operation?

A: Yes, the multi-station ATC (Automatic Tool Changer) allows for extended unattended operation, making it perfect for lights-out manufacturing.

Q: What kind of technical support does Mirrordick offer?

A: We provide lifelong free system upgrade services and unlimited technical support for machining processes. Our global network ensures responsive assistance.

Q: Is the control system easy to learn for new operators?

A: Absolutely. The Windows-based CNC system is intuitive and user-friendly, reducing the training time required for new operators.

Q: Can the machine be integrated into an existing automated production line?

A: Yes, thanks to its open automation data ports and network capabilities, the AD45 can be seamlessly integrated into automated cells and Industry 4.0 systems.

Phone

Phone