Detailed Description

The Mirrordick AM250R Precision Double-Head EDM machine represents the pinnacle of electrical discharge machining technology. Designed for manufacturers who demand extreme accuracy, mirror-like surface finishes, and maximum productivity, this machine is a cornerstone for modern, automated production lines.

Its innovative double-head design allows for simultaneous machining of two identical or different workpieces, doubling your output without occupying additional factory floor space. Equipped with a state-of-the-art Windows-based CNC system, the AM250R offers seamless network connectivity and open data ports, making it fully compatible with Industry 4.0 and smart factory concepts. Built with robust components and backed by Mirrordick core patented technologies, this machine ensures exceptional stability, durability, and precision for the most demanding applications.

Key Features

Dual Independent Machining Heads: Enable simultaneous processing of two workpieces, maximizing throughput and efficiency.

True Mirror Surface Finish: Achieves superb surface quality (e.g., Ra ≤ 0.1μm), eliminating the need for manual polishing.

Advanced ATC (Automatic Tool Changer): Supports extended unmanned operation with a multi-position electrode library for automatic electrode changing.

High-Precision 5-Axis System: Provides complex angle machining capabilities for intricate geometries and deep cavity applications.

Intelligent Pulse Power Supply: Adaptive technology optimizes machining parameters in real-time for speed and electrode wear reduction.

Automatic Oil Tank Elevation System: Enhances operational safety and convenience.

3D On-Machine Detection System (Optional): Allows for in-situ workpiece inspection, reducing setup times and ensuring accuracy.

User-Friendly Windows CNC System: Features open data interfaces for easy integration into MES and automated production environments.

High precision double heads cow head EDM machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

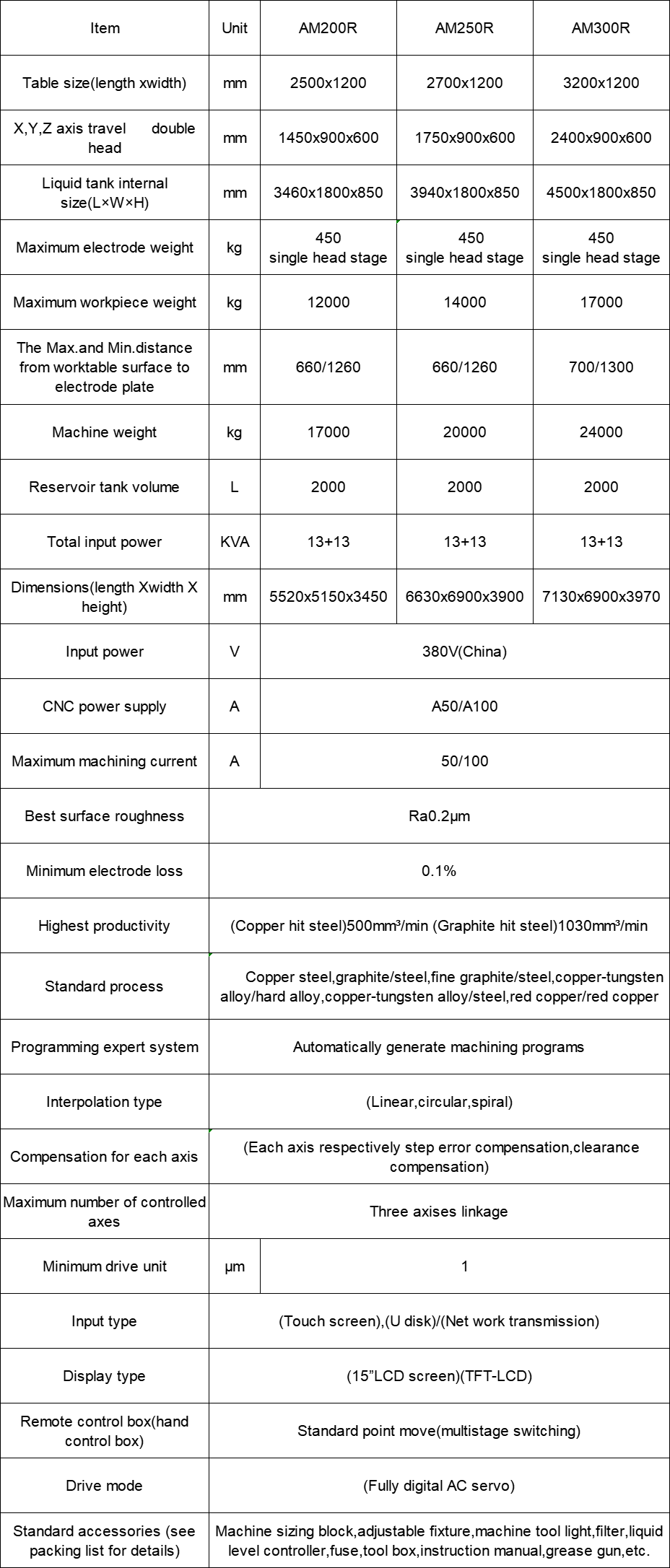

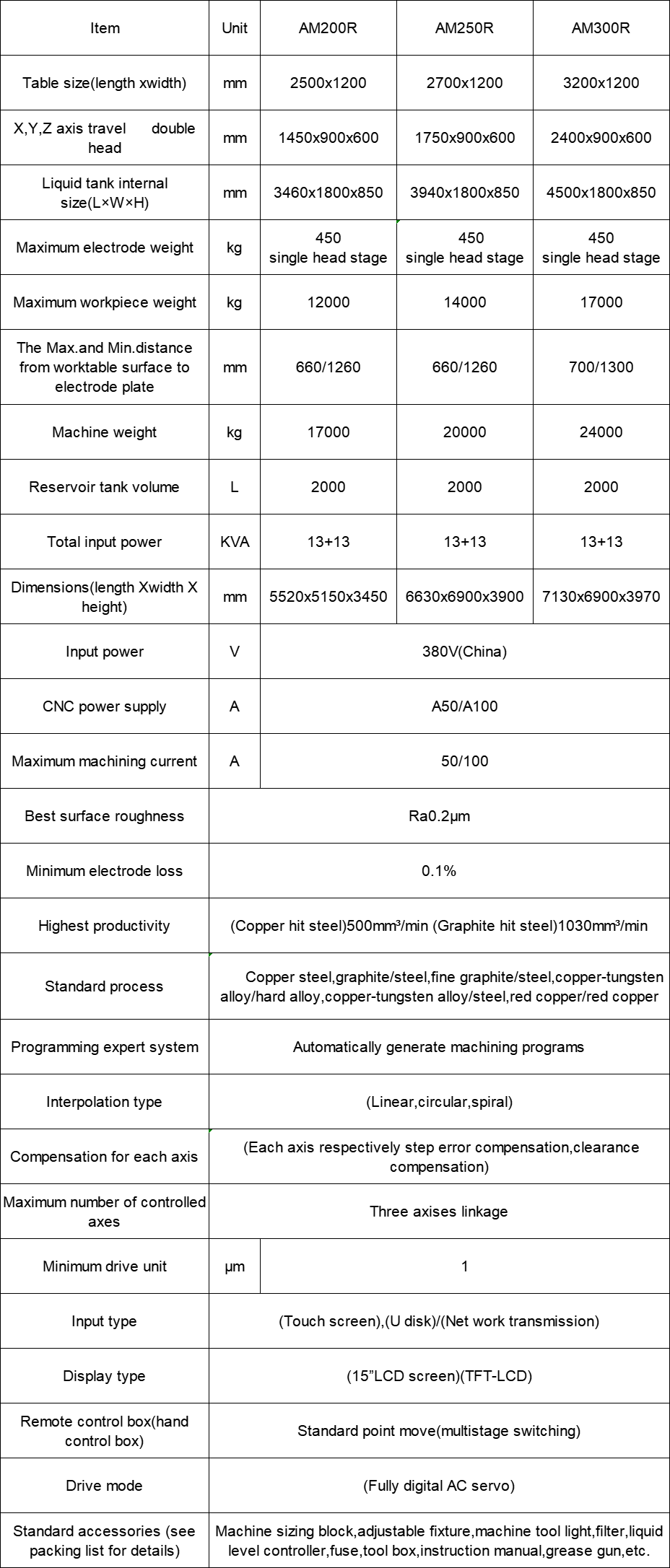

Parameter

Benefits

Double Your Productivity: The twin-head design effectively doubles your capacity, significantly reducing per-part cost and lead times.

Superior Part Quality: Consistently produce components with exceptional surface finishes and dimensional accuracy, enhancing your product quality.

Reduce Labor Costs: Capable of running lights-out (unmanned) for extended periods, optimizing labor allocation and reducing operational expenses.

Future-Proof Investment: Industry 4.0 readiness ensures your investment is protected, allowing for easy integration into smarter digital factories.

Unmatched Technical Support: Backed by Mirrordick commitment to "lifetime service," including free system upgrades and unlimited machining process support.

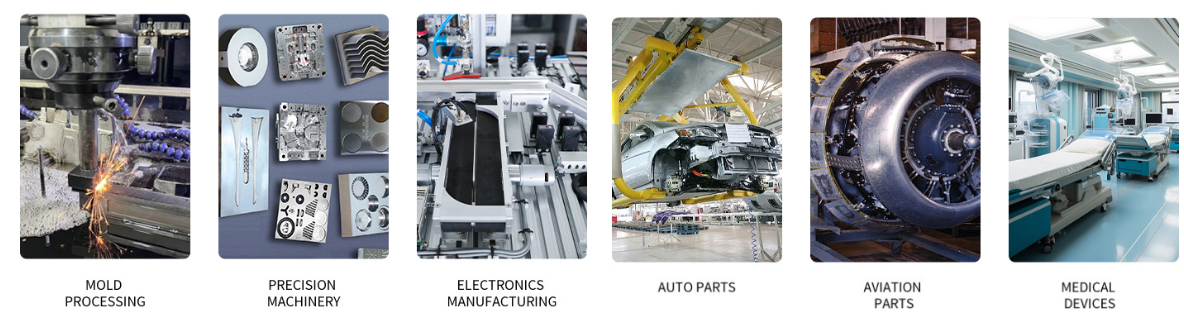

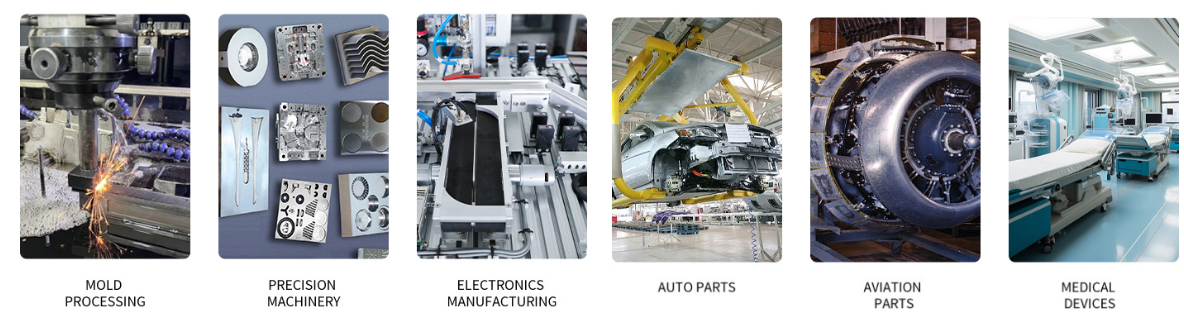

Application Industries

Precision Mold Manufacturing: Injection molds, die-casting molds, stamping molds, especially for optical lenses, cosmetic containers, and automotive parts.

Aerospace & Aviation: Manufacturing of heat-resistant alloy components, turbine blades, and other critical parts.

Medical Device Manufacturing: Production of surgical instruments, implantable devices, and micro-precision components.

Automotive Industry: Prototyping and production of key components for engines, transmissions, and sensors.

Electronics & Micro-Machining: Manufacturing of connectors, semiconductor parts, and other delicate components.

FAQ (Frequently Asked Questions)

Q: What is the typical surface finish (Ra) achievable with the AM250R?

A: Under optimal conditions, the AM250R can achieve a mirror surface finish of Ra ≤ 0.1μm, often eliminating the need for subsequent polishing.

Q: How does the double-head feature improve my ROI (Return on Investment)?

A: By machining two parts simultaneously, you effectively double your output capacity without doubling your machine footprint or energy consumption, leading to a faster return on your investment.

Q: Is the machine compatible with automated production lines?

A: Absolutely. With its open data ports, automatic electrode changer (ATC), and optional 3D detection, the AM250R is designed for seamless integration into robotic cells and MES systems.

Q: What kind of technical support does Mirrordick offer?

A: We provide comprehensive support, including installation, training, and lifelong free system software upgrades. Our "once a customer, lifetime service" policy ensures you have unlimited access to our machining expertise.

Q: What is the difference between this and a standard EDM machine?

A: The AM250R is a premium mirror EDM with a double-spindle design. It focuses on ultra-fine finishes and high-volume production, unlike standard EDMs which are typically single-head and prioritize roughing or semi-finishing.

Phone

Phone