Product Brief Introduction

The AM80 Precision Bull Head EDM machine Tool, equipped with a user-friendly Windows-based control system, is designed for high-precision mirror surface finishing and complex mold manufacturing. Ideal for industries requiring extreme accuracy and superior surface quality, this machine ensures efficient, stable, and automated operation—making it a perfect solution for tooling, aerospace, automotive, and medical manufacturing sectors.

High precision mirror machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

C axis

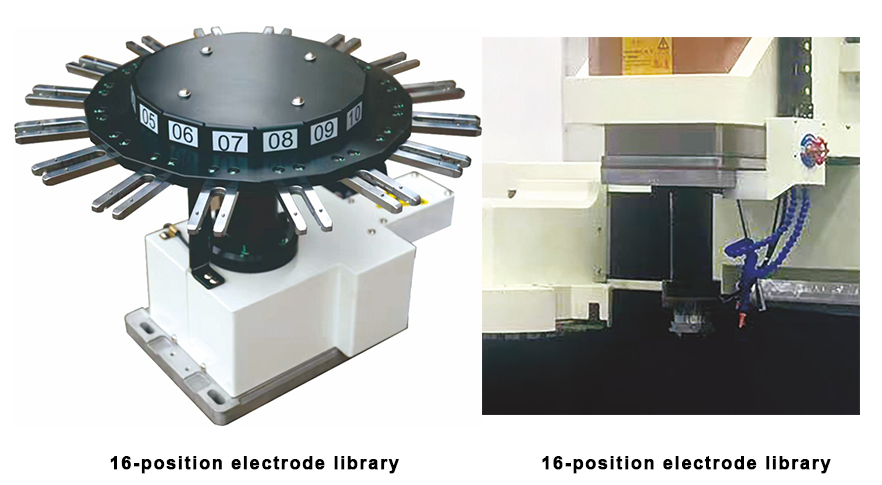

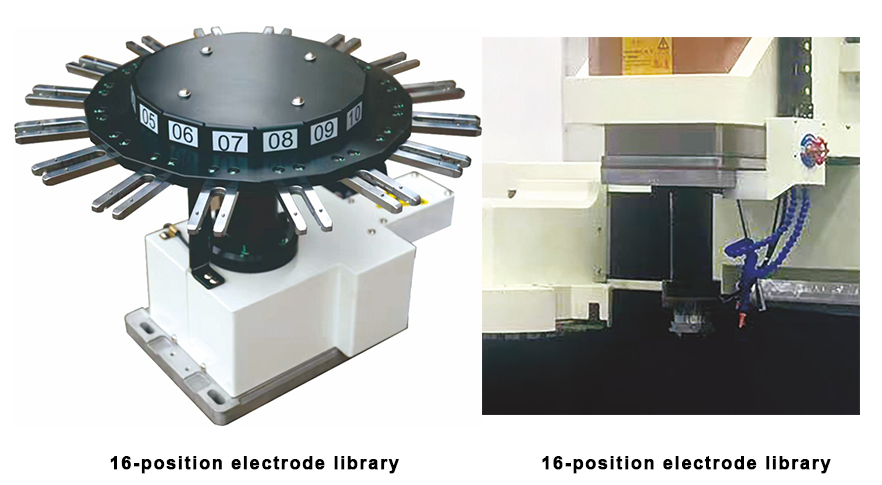

16-position ATC electrode library

Spark oil constant temperature device

Stabilizer

Quick Chuck

Mechanical automatic upper and lower doors

Parameter

Product Description

Mirrordick, a high-tech enterprise specializing in the R&D and production of precision Mirror EDM machines, introduces the AM80—a state-of-the-art bull head type EDM machine built for precision and reliability.

Based in Shenzhen with production facilities in Heyuan, Mirrordick combines core patented technology with continuous innovation to deliver machines that meet the highest international standards. The AM80 model features a Windows-integrated control system that supports network data transmission and offers open automation interface options, including auto oil tank lifting, 3D on-machine detection, and multi-station ATC electrode changer.

This machine is engineered to help customers achieve intelligent manufacturing, improve production efficiency, and embrace Industry 4.0 trends. With Mirrordick commitment to lifetime free system upgrades and technical support, the AM80 provides a worry-free investment for businesses worldwide.

Key Features

Windows Control System: Easy-to-use interface supporting real-time monitoring, file transfer, and remote operation.

Bull Head Structure: Enhanced rigidity and stability suitable for heavy-duty and high-precision tasks.

mirror surface EDM Technology: Delivers superior surface finish up to mirror-like quality.

3D On-Machine Measuring: Allows in-process inspection without transferring workpieces.

Multi-Station ATC: Automatic tool changer supports uninterrupted processing with multiple electrodes.

Auto Oil Tank Lifting: Improves operational convenience and reduces manual intervention.

Open Data Ports: Facilitates integration with MES/ERP systems and IoT-based smart factories.

Energy-Saving Design: Reduced power consumption and dielectric fluid usage.

Advantages

High Precision & Repeatability: Achieves tight tolerances and consistent results even in complex geometries.

User-Friendly Operation: Windows OS allows quick learning and ease of use.

Automation Ready: Supports unattended operation and fits into automated production lines.

Global Service Support: Mirrordick has experience centers in Vietnam and India, and partners worldwide.

Lifetime Free Upgrades: Customers enjoy ongoing software and system support at no extra cost.

Award-Winning Technology: Recognized with National Patent Awards and Mechanical Innovation Awards.

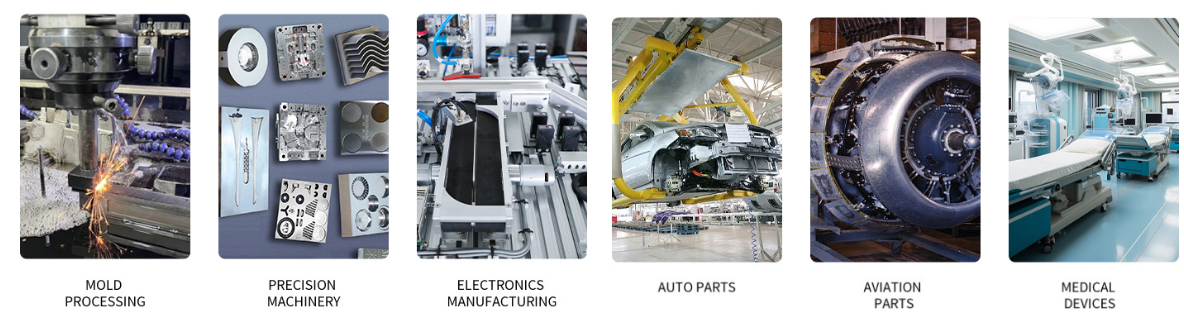

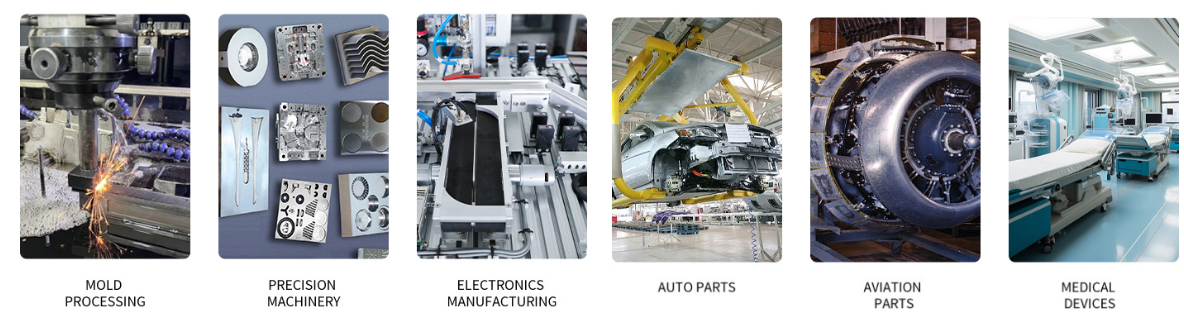

Application Industries

Mold & Die Manufacturing

Aerospace Components

Automotive Parts

Medical Device Manufacturing

Precision Machinery

Consumer Electronics

Energy Equipment

Semiconductor Processing

Frequently Asked Questions (FAQ)

Q1: What is the maximum surface finish quality the AM80 EDM can achieve?

A: The AM80 can achieve mirror-quality surface finishes, typically under Ra 0.1µm, depending on material and settings.

Q2: Does it support automated production lines?

A: Yes, with open data ports support for IoT, RS-232, and Ethernet interfaces, it can be integrated into fully automated smart factories.

Q3: What kind of training is provided?

A: We provide online and on-site training, along with detailed manuals and video tutorials. Lifetime technical support is included.

Q4: Can the machine handle large workpieces?

A: The bull head design offers high stability and capacity for medium to large workpieces. Custom table sizes are available.

Q5: Is the Windows system secure for industrial use?

A: Yes, the system is built for industrial use with stable performance and virus protection recommendations.

Q6: What after-sales services do you offer?

A: We offer lifetime free system upgrades, unlimited process support, and have service points in Vietnam, India, and other regions.

Phone

Phone