Product Overview

The AR65 Windows System Mirror Spark Machine is a new-generation high-precision EDM (Electrical Discharge Machining) equipment designed for industries that require superior accuracy, smooth surface finishes, and highly efficient mold processing. Manufactured by Mirrordick, a leading enterprise specializing in mirror EDM technology, this model combines refined spark erosion technology with an advanced Windows operating system, enabling greater automation, user-friendly operation, and seamless integration with smart manufacturing environments.

With its robust structure, intelligent CNC control, and mirror-finish machining capability, the AR65 is the ideal solution for manufacturers in automotive, aerospace, medical, electronics, and precision mold-making industries.

High precision mirror machine

Automatic lifting of oil tank

Windows control system(multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

Spark oil constant temperature device

60 workpiece coordinate systems

Special option

C axis

16-position ATC electrode library

Stabilizer

Quick Chuck

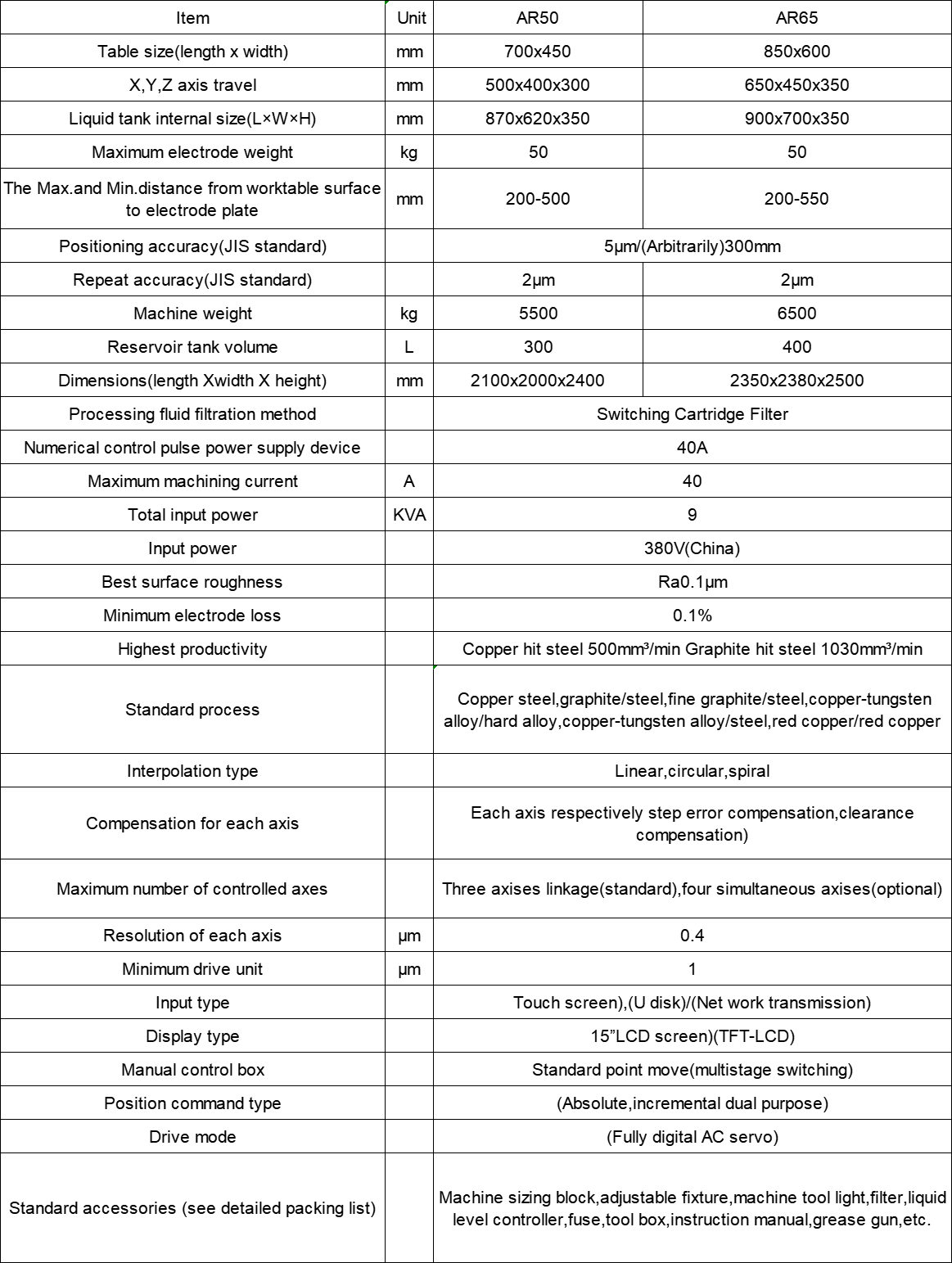

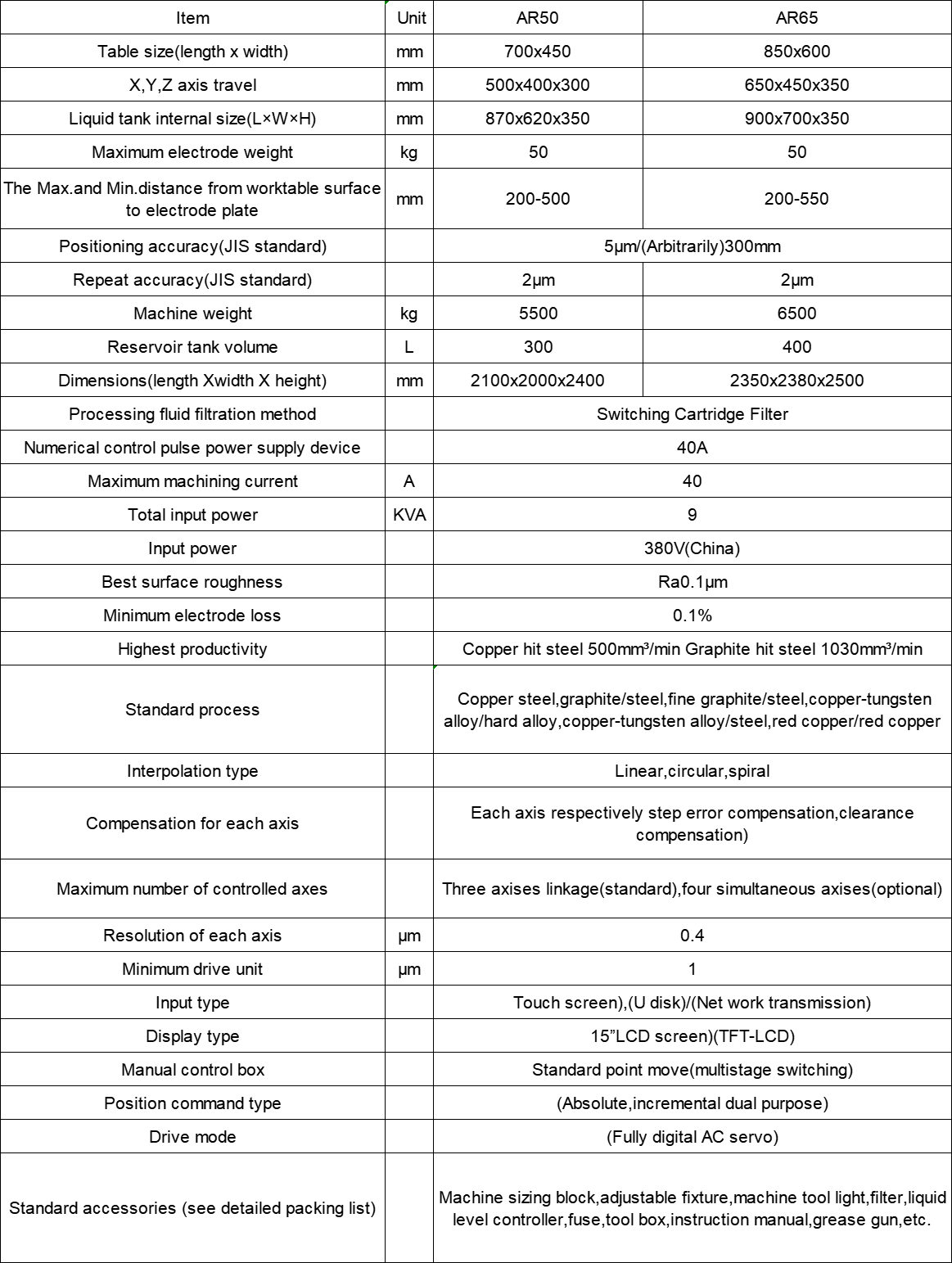

Parameter

Detailed Product Introduction

The AR65 is specifically engineered to meet the increasing demand for complex geometries and fine surface finishes. By adopting Mirrordick patented mirror spark technology, it ensures sub-micron accuracy while delivering mirror-like surfaces, reducing or even eliminating the need for post-polishing.

The integrated Windows-based CNC control platform makes the system highly intuitive and allows open connectivity with factory networks. Automated functions such as multi-station electrode libraries, 3D online measurement, and automatic oil tank lifting significantly improve efficiency and ensure reliable operation even during long production runs.

Designed in line with Industry 4.0 standards, the AR65 not only delivers unmatched machining performance but also supports intelligent automation for future-oriented smart manufacturing.

Key Features

Windows-Based CNC Control – Provides intuitive operation, automated data ports, and strong compatibility with networked systems.

Mirror Spark Technology – Achieves ultra-smooth finishes with exceptional precision, reducing polishing and secondary processing.

3D Online Detection – Real-time measurement ensures machining accuracy and minimizes errors during production.

Automatic Oil Tank Lifting – Simplifies maintenance and improves overall machine efficiency.

Multi-Station ATC Electrode Library – Supports automated electrode replacement, increasing flexibility in complex machining.

Rigid Machine Construction – Heavy-duty base ensures vibration-free stability and consistent accuracy.

Energy-Saving System – Optimized discharge efficiency reduces power consumption while maintaining productivity.

User-Friendly Interface – Easy-to-use controls, fault diagnosis, and alarm systems simplify operation for technicians.

Product Advantages

Precision at Scale – Capable of delivering mirror-level finishes with high repeatability across long production runs.

Automation Ready – Equipped with ATC, 3D detection, and Windows automation to reduce downtime and labor costs.

Future-Proof Integration – Fully compatible with Industry 4.0 requirements, allowing network connectivity and data tracking.

Reduced Processing Costs – Eliminates or reduces secondary polishing, saving time and material costs.

Stable and Reliable – Strong machine frame and advanced cooling systems ensure consistent long-term performance.

Global Service Guarantee – Mirrordick provides lifetime free technical support, upgrades, and process consultation.

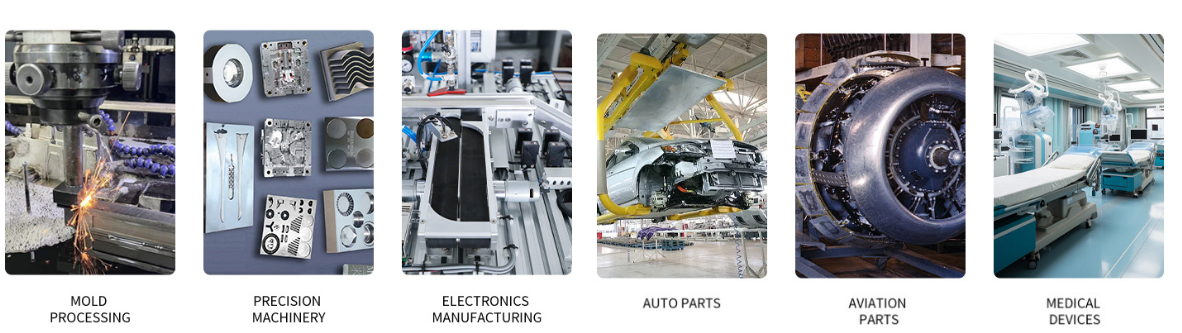

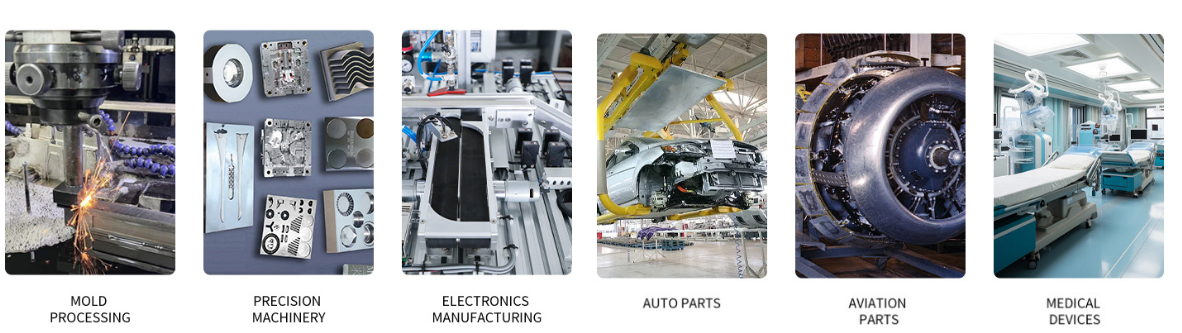

Application Fields

The AR65 Windows system mirror spark machine is widely applied in:

Mold Manufacturing – Plastic molds, injection molds, precision dies, and die-casting molds.

Automotive Industry – High-precision engine parts, transmission components, and complex connectors.

Aerospace Sector – Precision turbine parts, lightweight structural components, and complex profiles.

Medical Industry – Surgical tools, implant components, and high-tolerance medical devices.

Electronics Manufacturing – Micro-connectors, semiconductor housings, and precision enclosures.

Tool & Die Applications – High-accuracy tooling solutions with reduced post-processing.

FAQ (Frequently Asked Questions)

Q1: What is the main advantage of the AR65 compared to conventional EDM machines?

A1: The AR65 offers mirror-finish machining with superior accuracy and is equipped with Windows-based intelligent controls, enabling higher efficiency and easier integration into modern smart factories.

Q2: Can the AR65 handle complex and small-sized molds?

A2: Yes, the AR65 is specifically designed for complex geometries, micro-features, and fine cavities, making it suitable for high-precision mold manufacturing.

Q3: How does the Windows system benefit operators?

A3: The Windows CNC platform provides a user-friendly interface, automated data handling, and strong compatibility with existing factory systems, simplifying operation and improving productivity.

Q4: What materials can be processed by the AR65?

A4: The AR65 can efficiently machine hardened steel, copper, tungsten carbide, and other conductive materials used in molds and precision parts.

Q5: What kind of after-sales service is available?

A5: Mirrordick provides free lifetime technical support, continuous process consulting, and free system upgrades, ensuring customers enjoy a worry-free ownership experience.

Phone

Phone