Product Brief Introduction

We provide you with the high-precision AM120R Precision Double-Head Spark Machine, engineered for exceptional mirror surface finishing, unparalleled production efficiency, and complex mold manufacturing. Suitable for precision micro-machining, multi-task automation, and achieving stringent surface quality requirements in the mold industry, etc. As a professional EDM machine manufacturer and supplier, Mirrordick is dedicated to helping you streamline production, reduce costs, and step into the era of intelligent manufacturing.

High precision double heads cow head

EDM machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

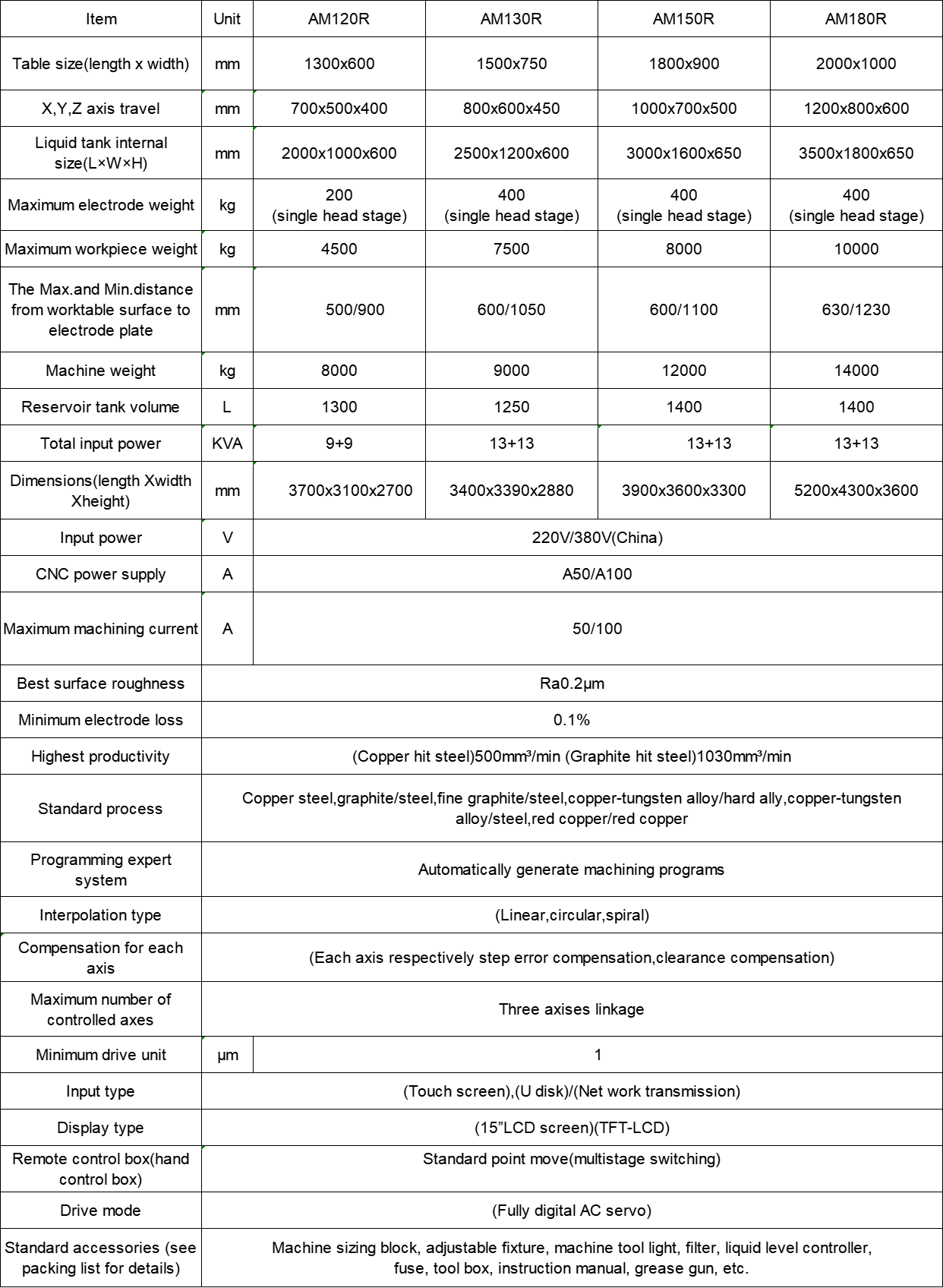

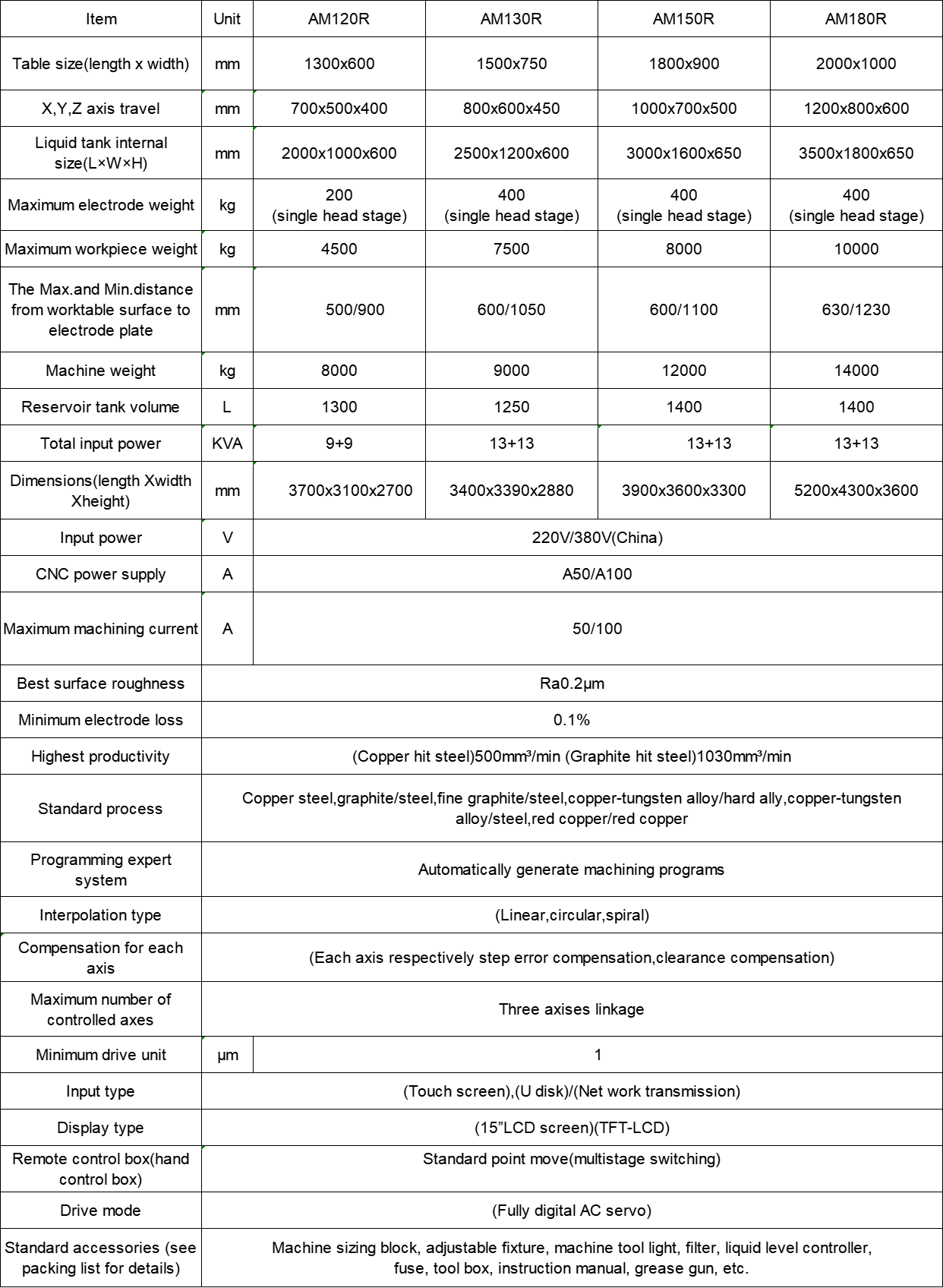

Parameter

Detailed Description

The AM120R Precision Double-Head Spark Machine from Mirrordick represents the pinnacle of innovation in electrical discharge machining. This CNC-controlled machine is designed for manufacturers who refuse to compromise on precision and productivity. Its unique dual-head design allows for simultaneous, independent operation on two workpieces or two different areas of a single, large workpiece, effectively doubling your output and maximizing machine utilization.

Built with a robust, thermally symmetrical structure and equipped with advanced linear guides, the AM120R ensures extreme rigidity and exceptional stability over long operating periods. This guarantees consistent, high-precision results even under continuous production demands. The machine is integrated with our user-friendly Windows-based CNC system, which supports network transmission and offers open automation data ports for seamless integration into smart factories and Industry 4.0 environments.

Mirrordick commitment to "Quality First, Service Forward" is embedded in every aspect of the AM120R, backed by our promise of lifetime free system upgrades and unlimited technical support.

Features & Benefits

Dual-Head Independent Design:Double Your Productivity: Process two workpieces or two tasks simultaneously, drastically reducing lead times and increasing ROI.

Precision Mirror Surface Technology:Achieve Superior Finishes: Eliminate the need for manual polishing. Obtain flawless, mirror-like surfaces (up to RA≤0.1μm) directly from the EDM process, saving time and costs.

Advanced Windows CNC System:User-Friendly & Smart Ready: Easy to learn and operate. Supports data connectivity for remote monitoring and DNC, paving the way for unmanned operation.

3D On-The-Fly Detection:Enhanced Accuracy & Confidence: Automatically detects electrode and workpiece positioning in real-time, minimizing setup errors and ensuring perfect accuracy.

Optional Multi-Station ATC:Unmatched Automation: The Automatic Tool Changer (ATC) allows for continuous, lights-out operation by automatically switching up to multiple electrodes.

Thermally Stable Structure:Unwavering Consistency: The rigid frame and linear guides resist thermal deformation, guaranteeing repeatable precision 24/7.

Oil Tank Auto-Lift System:Improved Operational Ergonomics: Makes workpiece loading and unloading easier, safer, and more efficient.

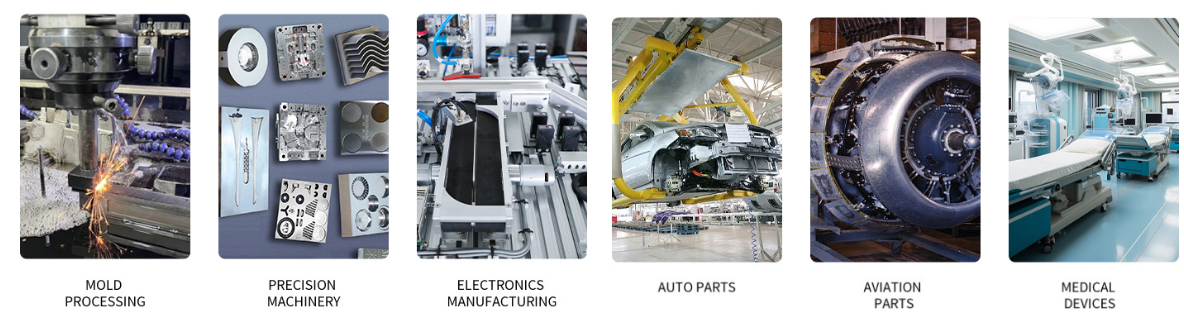

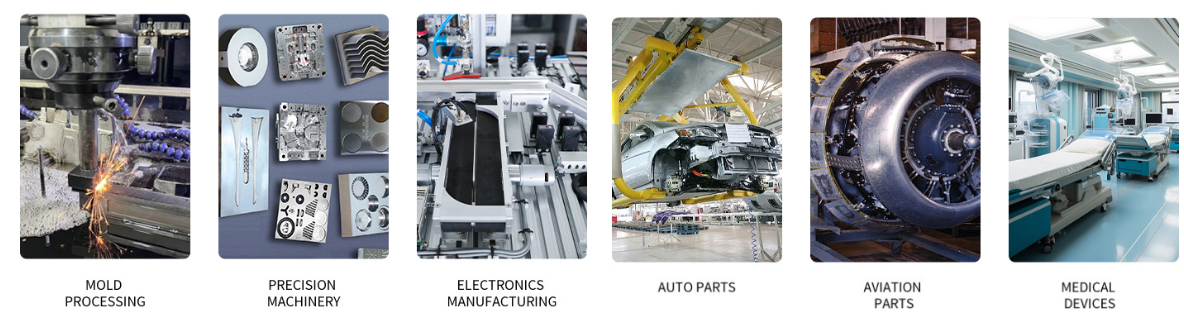

Application Industries

Precision Mold Manufacturing: Ideal for intricate injection molds, die-casting molds, forging dies, and powder metallurgy molds requiring high gloss surfaces.

Automotive Industry: Production of key components like gearboxes, engine components, and high-gloss interior trim molds.

Medical Device Manufacturing: For machining complex, high-precision parts for surgical instruments and medical implants.

Aerospace & Aviation: Manufacturing of heat-resistant alloy components and precision parts with tight tolerances.

Consumer Electronics: Fabrication of molds for smartphone casings, cosmetic parts, and other components demanding a perfect aesthetic finish.

Tungsten Steel & Hard Alloy Processing: Effortlessly machines hardened materials that are difficult to process with traditional methods.

FAQ

Q: What is the typical surface roughness (Ra) achievable with the AM120R?

A: With optimized settings and our proprietary technology, the AM120R can consistently achieve a superior mirror surface finish of RA ≤ 0.1 μm.

Q: Can the two heads operate completely independently?

A: Yes. The two machining heads are controlled independently, allowing you to run two different jobs with different programs, electrodes, and parameters at the same time.

Q: Is the Automatic Tool Changer (ATC) a standard feature?

A: The ATC is offered as a highly recommended optional configuration to meet specific automation needs. Please check the standard configuration list or contact our sales team for details.

Q: What kind of after-sales support does Mirrordick offer?

A: We provide comprehensive support, including installation guidance, operator training, lifetime free system software upgrades, and unlimited remote technical support for machining processes.

Q: Do you provide custom solutions based on our workpiece?

A: Absolutely. As a specialist manufacturer, we can discuss customizing solutions to fit your specific workpiece dimensions and technical requirements.

Phone

Phone