Product Introduction

The AM130R Precision Dual-Head EDM machine represents the pinnacle of efficiency and accuracy in electrical discharge machining. Engineered by Mirrordick, a leading innovator in precision EDM technology, this machine is built for mold shops that refuse to compromise on quality or throughput.

It tackles the core challenges of modern manufacturing: reducing cycle times, achieving flawless surface finishes without manual polishing, and maximizing machine uptime. With its revolutionary dual-head design, the AM130R doesn't just process two workpieces simultaneously; it effectively doubles your production capacity within the same factory footprint. Integrated with a user-friendly Windows-based CNC system and optional 3D online inspection, it's more than a machine—it's your partner in achieving intelligent, automated manufacturing and stepping into the era of Industry 4.0.

High precision double heads cow head

EDM machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

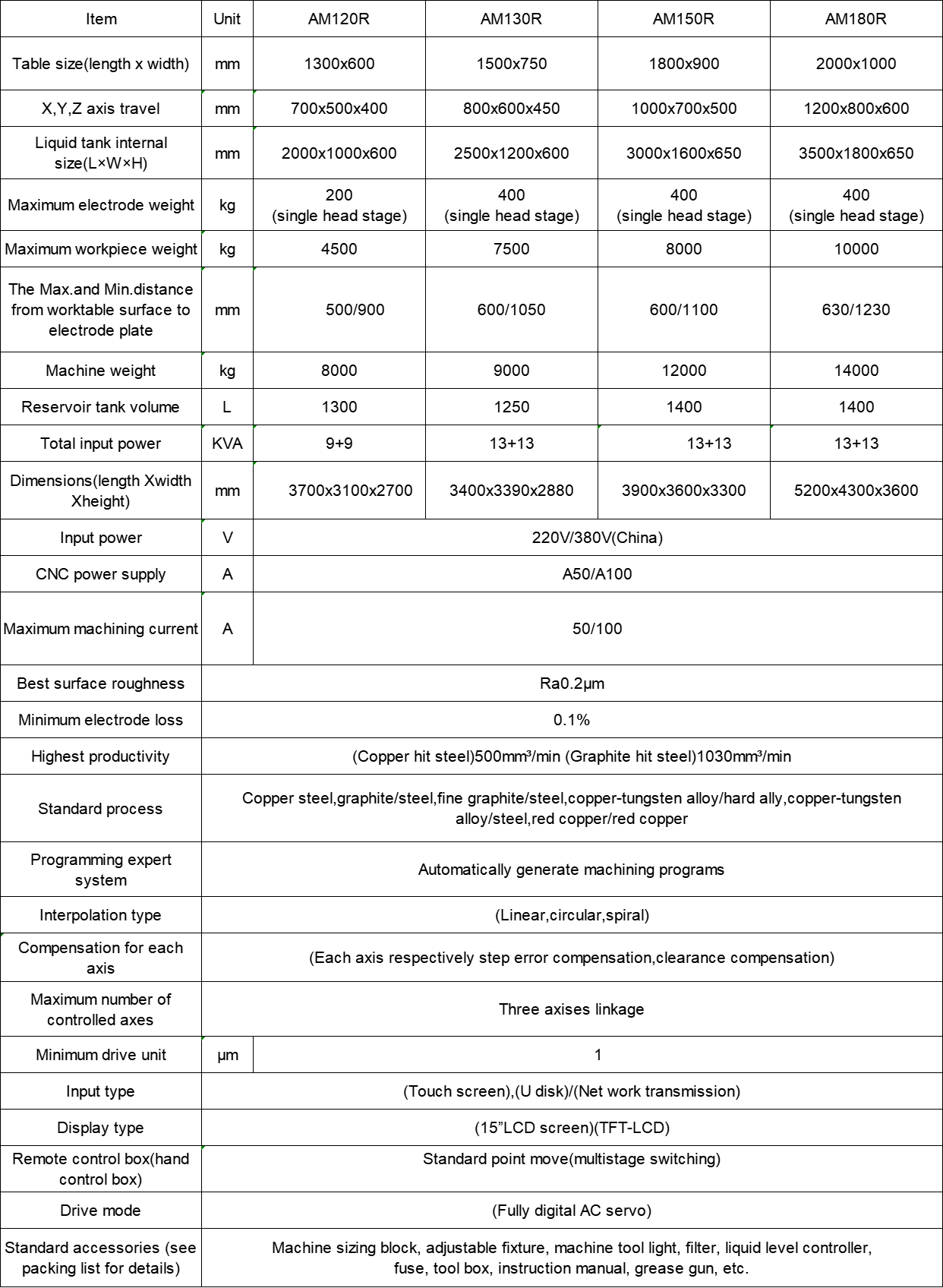

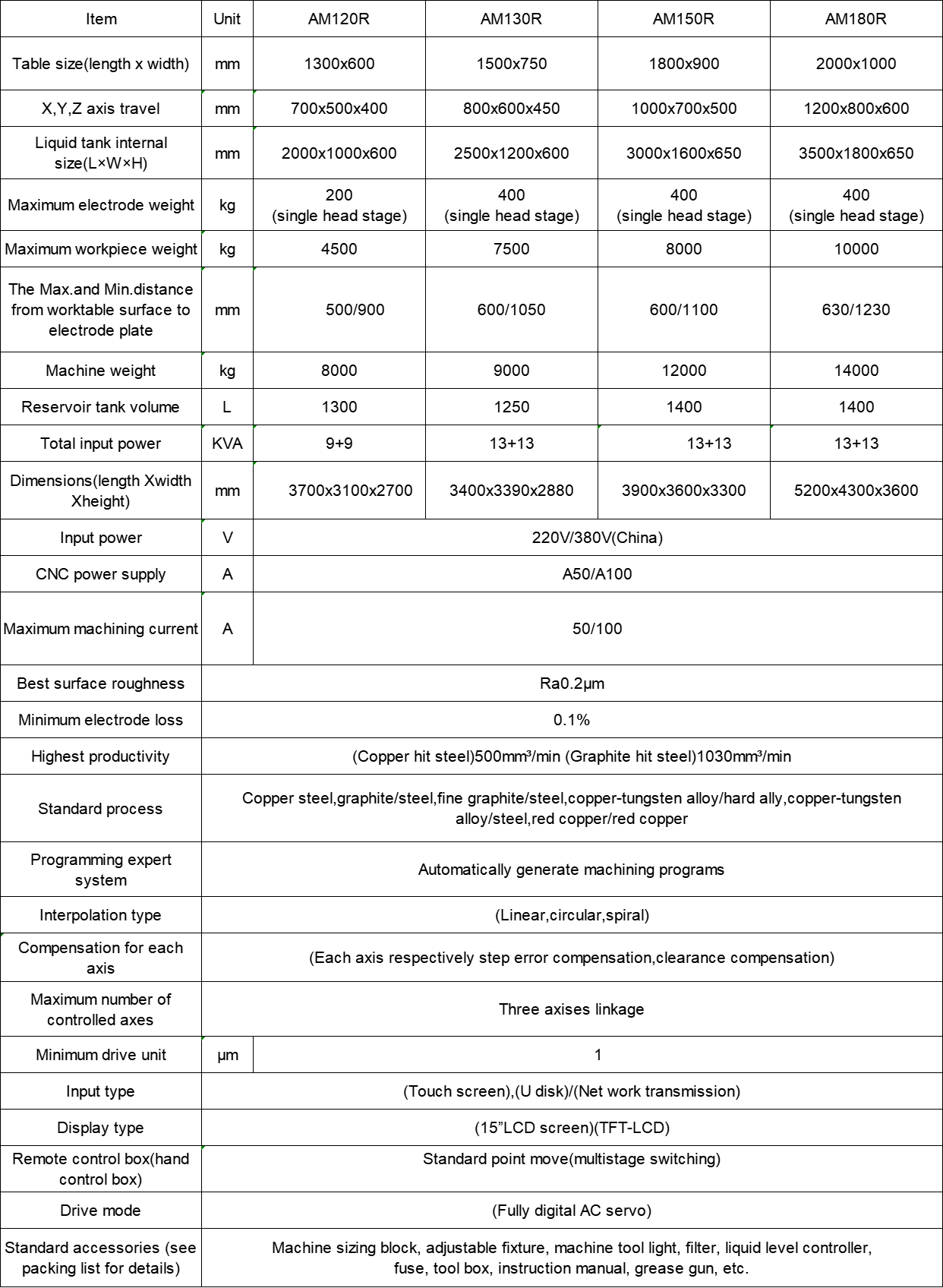

Parameter

Key Features

Dual-Head Independent Processing: Two independent CNC axes (Z/U) allow for simultaneous machining of two identical or different workpieces, drastically improving equipment utilization and production efficiency.

Superior Mirror Surface Finish: Advanced power supply technology and intelligent control algorithms ensure exceptional surface quality, achieving mirror finishes of Ra ≤ 0.1µm,

Windows-Based Intelligent CNC System: Features an open API data port for seamless network transmission and future integration into MES or smart factory systems.

High Rigidity & Thermal Stability: The machine utilizes a one-time cast mineral composite bed, offering excellent vibration damping and long-term geometric accuracy.

Advanced Automation Ready: Equipped with options for an Automatic Tool Changer (ATC), automatic electrode measurement, and an automatic oil tank lifting system, enabling lights-out

Benefits

Double Your Productivity: Machine two cavities, cores, or electrodes at once, slashing lead times and increasing ROI.

Eliminate Costly Hand Polishing: Achieve pre-polish or mirror finishes directly out of the machine, saving hundreds of labor hours and reducing human error.

Reduce Total Cost of Ownership: High reliability, energy-efficient generators, and minimal maintenance requirements keep your operational costs low.

Unmatched Precision & Consistency: Perfect for manufacturing high-precision molds for medical implants, optical components, and connectors where micron-level accuracy is non-negotiable.

Future-Proof Automation: The open architecture system easily connects to automation cells and Industry 4.0 data monitoring platforms.

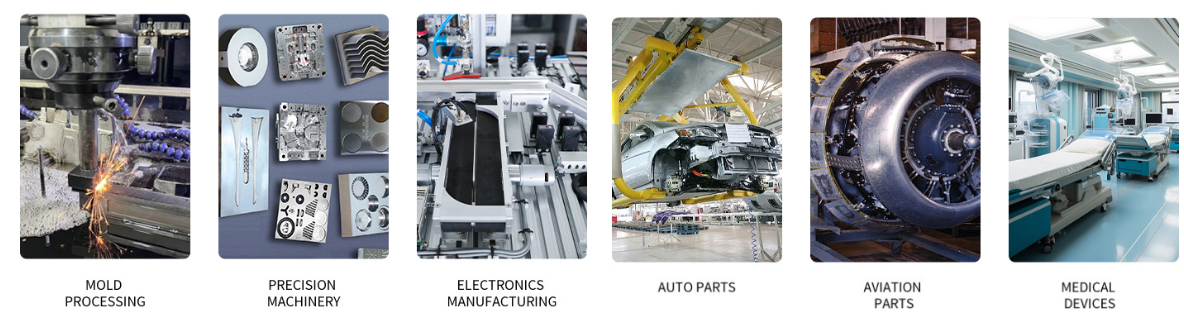

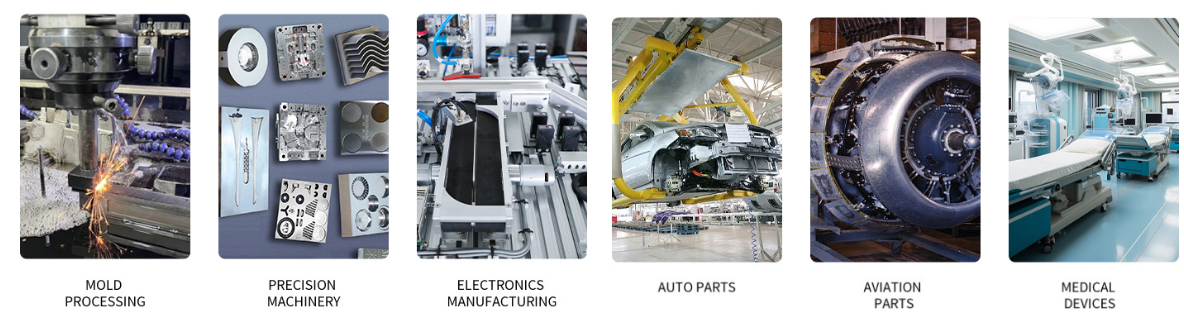

Application Industries

Automotive Mold: High-speed production of injection molds for light guides, lenses, and interior components.

Medical Device Mold: Manufacturing of micro-precision molds for surgical instruments, implantable devices, and drug delivery parts.

Consumer Electronics Mold: Machining of intricate cavities and cores for smartphone casings, connectors, and wearable technology.

Precision Engineering: Production of fine blanking dies, extrusion dies, and other tooling requiring the highest levels of accuracy.

FAQ

Q1: What is the maximum table load capacity for each head?

A: Each workhead is designed to handle a maximum load of 800kg, ensuring stability for most medium-to-large mold base processing.

Q2: Can the two heads work on two completely different jobs?

A: Yes, the two heads are controlled by independent CNC axes. This allows two different programs to run simultaneously on two different workpieces.

Q3: What is the typical surface finish (Ra) achievable?

A: Under optimized parameters, the AM130R can consistently achieve a superior mirror surface finish of Ra ≤ 0.1µm.

Q4: Do you provide support for automation integration?

A: Absolutely. As part of our "Lifetime Service" commitment, our technical team provides unlimited free support for machining processes and guidance on integrating with robotic arms and automation systems.

Q5: What is the power consumption of this machine?

A: The machine utilizes an energy-saving pulse power supply. Specific consumption depends on the machining parameters, but it is designed for high efficiency.

Phone

Phone