Product Introduction

Mirrordick, a leading high-tech enterprise specializing in the R&D and manufacturing of precision mirror EDM machines, proudly presents the AM180R Precision Double-head Spark Machine. Engineered for excellence, this machine embodies our core philosophy of "Quality First, Service Forward, and Customer Supreme." Designed to meet the stringent demands of modern manufacturing, the AM180R combines robust German-engineered mechanics with our advanced Windows-based intelligent control system. It is the ultimate solution for manufacturers seeking to achieve superior surface finishes, exceptional accuracy, and unmanned automated production, propelling your workshop towards Industry 4.0.

Detailed Product Overview

The AM180R is a state-of-the-art CNC Electrical Discharge Machine (EDM) featuring a revolutionary double-head design. This configuration allows for simultaneous or independent machining of two workpieces, drastically reducing idle time and doubling productivity. Equipped with our self-developed MDS-500 intelligent power supply and a rigid cast iron structure, it guarantees stable machining of complex geometries with surface finishes reaching RA ≤ 0.1µm. Perfect for high-precision industries like automotive, aerospace, and medical mould manufacturing, the AM180R is more than a machine—it's your partner in achieving manufacturing excellence.

High precision double heads cow head

EDM machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

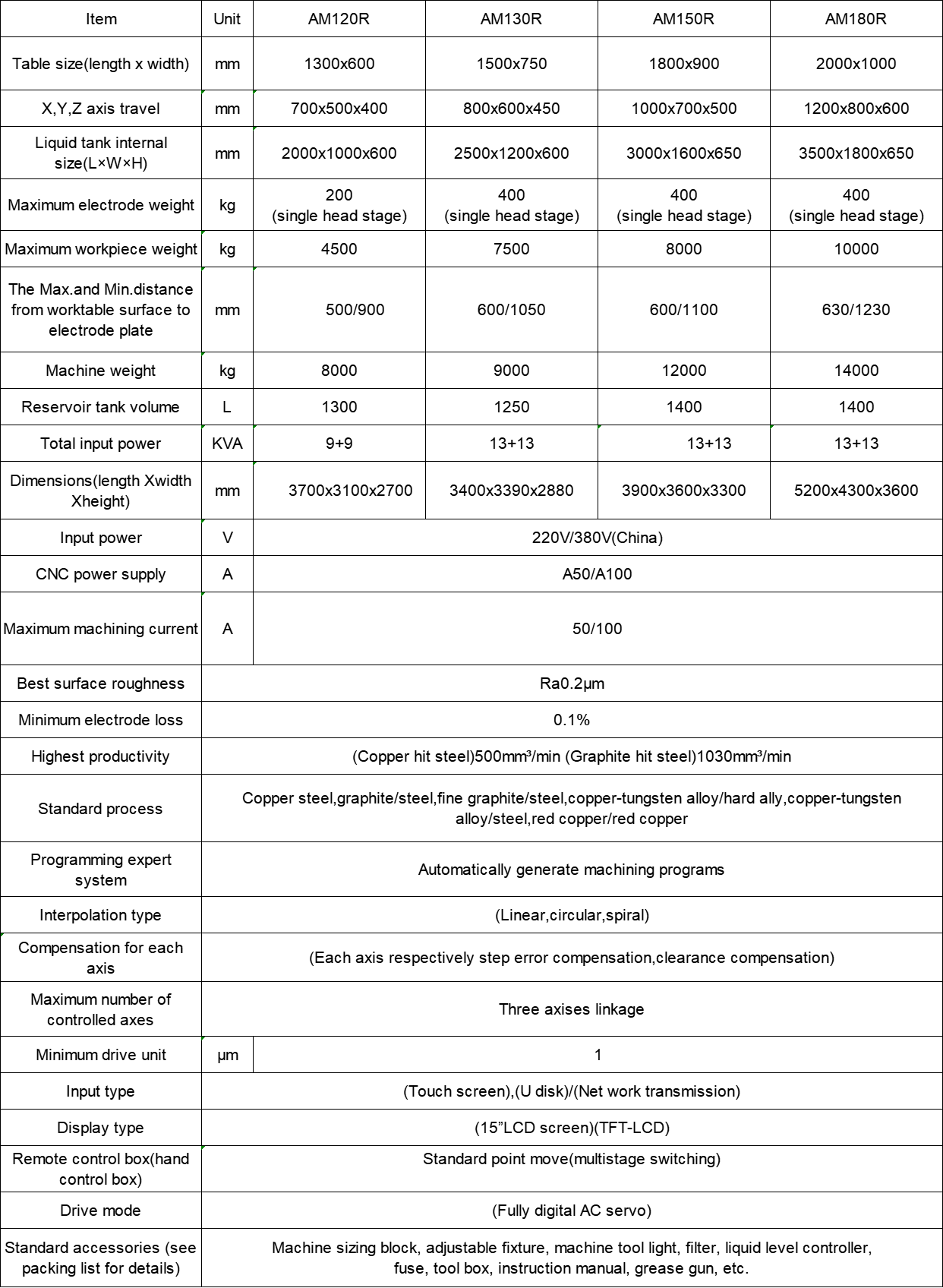

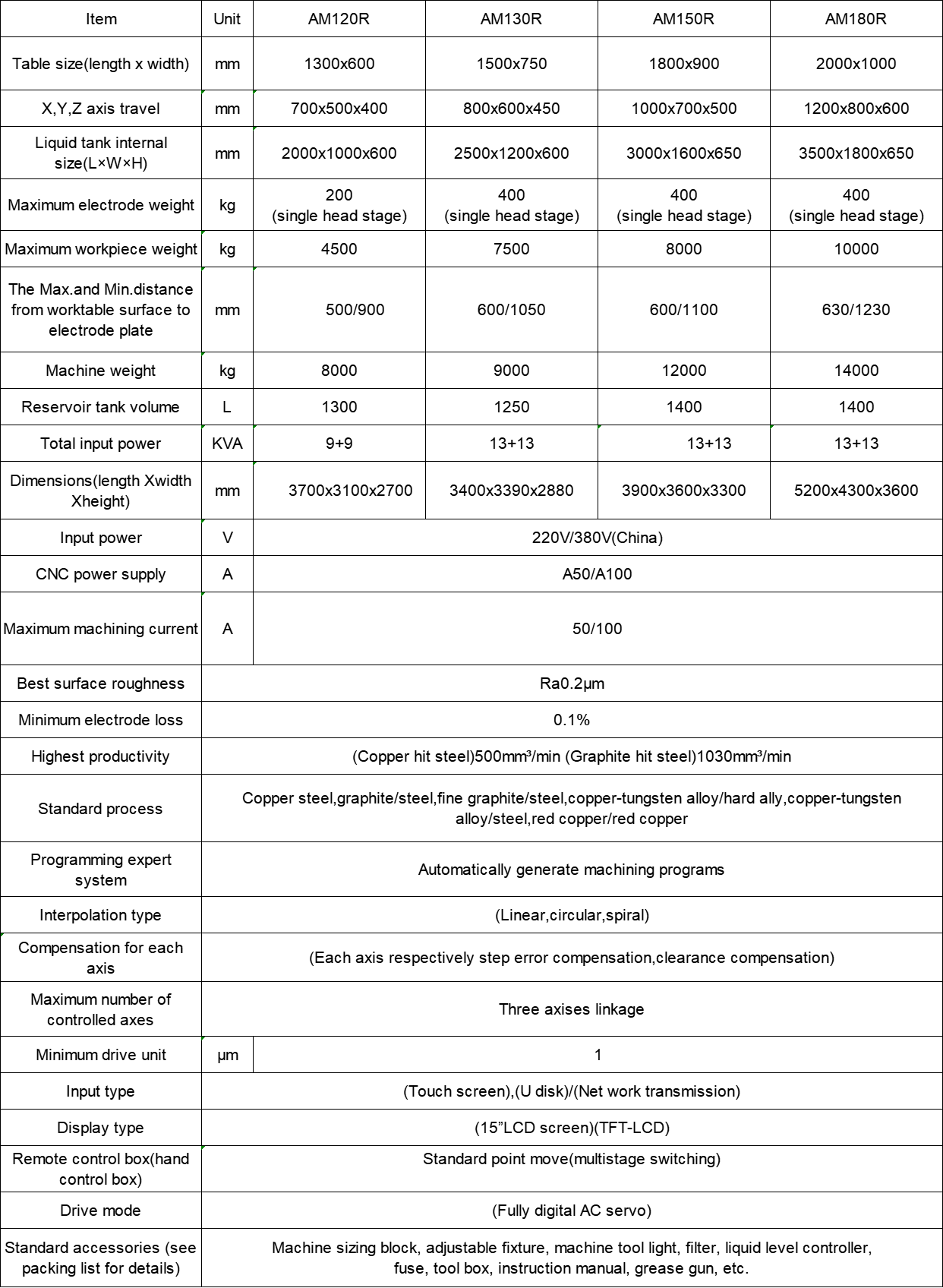

Parameter

Key Features & Technical Specifications

Dual-Head Design: Two independent machining heads operate simultaneously, maximizing throughput and efficiency for batch production.

Mirror Surface Technology: Achieves exceptional surface finishes of RA ≤ 0.1µm, eliminating the need for manual polishing.

Advanced MDS-500 Power Supply: Ensures high-speed, stable, and low-electrode-wear machining, even with complex geometries.

Windows-Based CNC System: User-friendly interface supports network transmission, data port openness, and easy integration into smart factories.

Automated Tool Changer (ATC): Optional 8- or 16-position ATC enables uninterrupted, lights-out operation.

3D On-The-Machine Detection: Integrated probing for automatic workpiece setting and in-process inspection, ensuring pinpoint accuracy.

Auto Oil Tank Lift System: Standard feature for operator convenience and a cleaner working environment.

Robust Construction: German-designed mechanics with high-grade cast iron provide unparalleled thermal stability and vibration damping.

Technical Specifications:

Table Size: 800mm x 600mm

Max Workpiece Weight: 1500 kg

X/Y/Z Travel: 800mm / 600mm / 500mm

Surface Finish: RA ≤ 0.1µm

Positioning Accuracy: ≤ ±0.005mm

Control System: Mirrordick Windows CNC

Core Advantages & Benefits

Double the Productivity: The dual-head design fundamentally changes your production economics, allowing you to complete two jobs in the time of one.

Unmatched Precision & Finish: Consistently deliver perfect mirror finishes and tight tolerances, enhancing the quality and value of your final products.

Reduce Total Cost of Ownership (TCO): Our low electrode wear technology and energy-efficient design lower consumable and energy costs. Combined with lights-out automation capabilities, it significantly reduces labor costs.

Future-Proof Automation: Ready for Industry 4.0. Open data ports and network capabilities allow for seamless integration into MES and ERP systems for full production monitoring and optimization.

Worry-Free Ownership: Backed by Mirrordick "One-Time Customer, Lifetime Service" commitment, including free lifetime system upgrades and unlimited machining support.

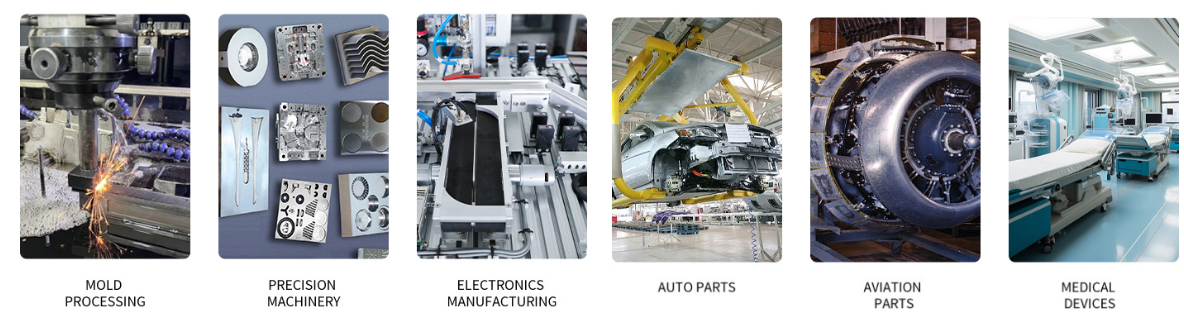

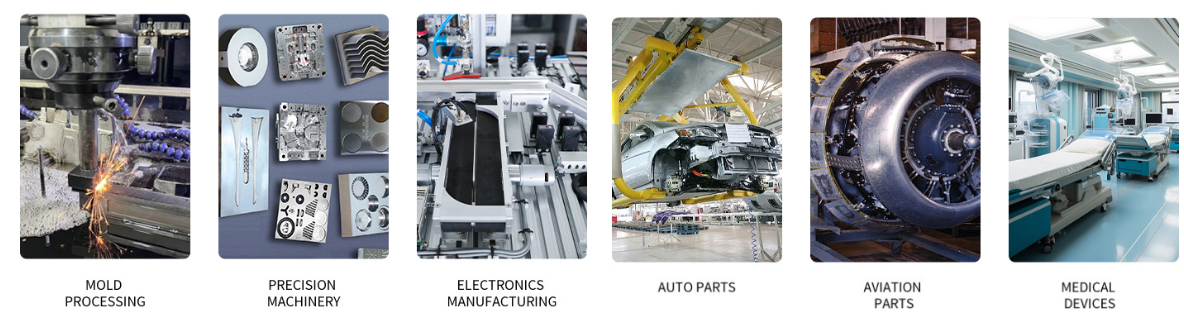

Target Application Industries

Injection Mould & Die Making: For core/cavity, inserts, and delicate texturing.

Automotive: Manufacturing of gears, micro-gears, fuel injector components, and other high-precision parts.

Aerospace: Production of turbine blades, engine components, and heat-resistant alloys.

Medical Device Manufacturing: Creating surgical instruments, implant components, and micro-moulds.

Precision Engineering: Applicable for any industry requiring micron-level accuracy and flawless surface integrity.

Frequently Asked Questions (FAQ)

Q: What is the main benefit of the double-head design?

A: It dramatically increases productivity by enabling the machining of two identical or different parts at the same time, making it ideal for batch production and reducing per-part cost.

Q: Can this machine run unattended?

A: Yes, with the optional Multi-Position ATC (Automatic Tool Changer) and 3D automatic detection system, the AM180R can perform continuous, lights-out operation for 24/7 production.

Q: How does your after-sales service work for international clients?

A: We have customer experience centers in Vietnam and India and partners globally. We provide remote online support, and on-site training and maintenance can be arranged through our network. System upgrades are provided free for life via remote access.

Q: Is the control system easy to learn for operators?

A: Absolutely. Our Windows-based CNC system features an intuitive, graphical interface similar to standard PC operations, reducing the learning curve and minimizing training time.

Q: What materials can the AM180R machine?

A: It can efficiently process all conductive materials, including hardened steel, tungsten carbide, titanium alloys, and superalloys.

Phone

Phone