Product Description:

Mirrordick AM150R is a state-of-the-art double-head EDM machine engineered for manufacturers who require ultra-fine surface quality and repeatable precision. Equipped with dual independent CNC heads, the machine allows simultaneous or independent operation, significantly reducing production time and improving throughput. The robust construction, coupled with intelligent adaptive control systems, ensures stability and accuracy even during long-hour operations. Whether you're working with hardened steel, titanium, carbide, or other conductive materials, the AM150R delivers flawless mirror-like finishes and tight-tolerance results.

High precision double heads cow head

EDM machine

Windows control system (multilingual)

Network transmission port

PIKA ultra-precision mirror discharge circuit

60 workpiece coordinate systems

Special option

Spark oil constant temperature device

Electric control box thermostat

Stabilizer

Quick Chuck

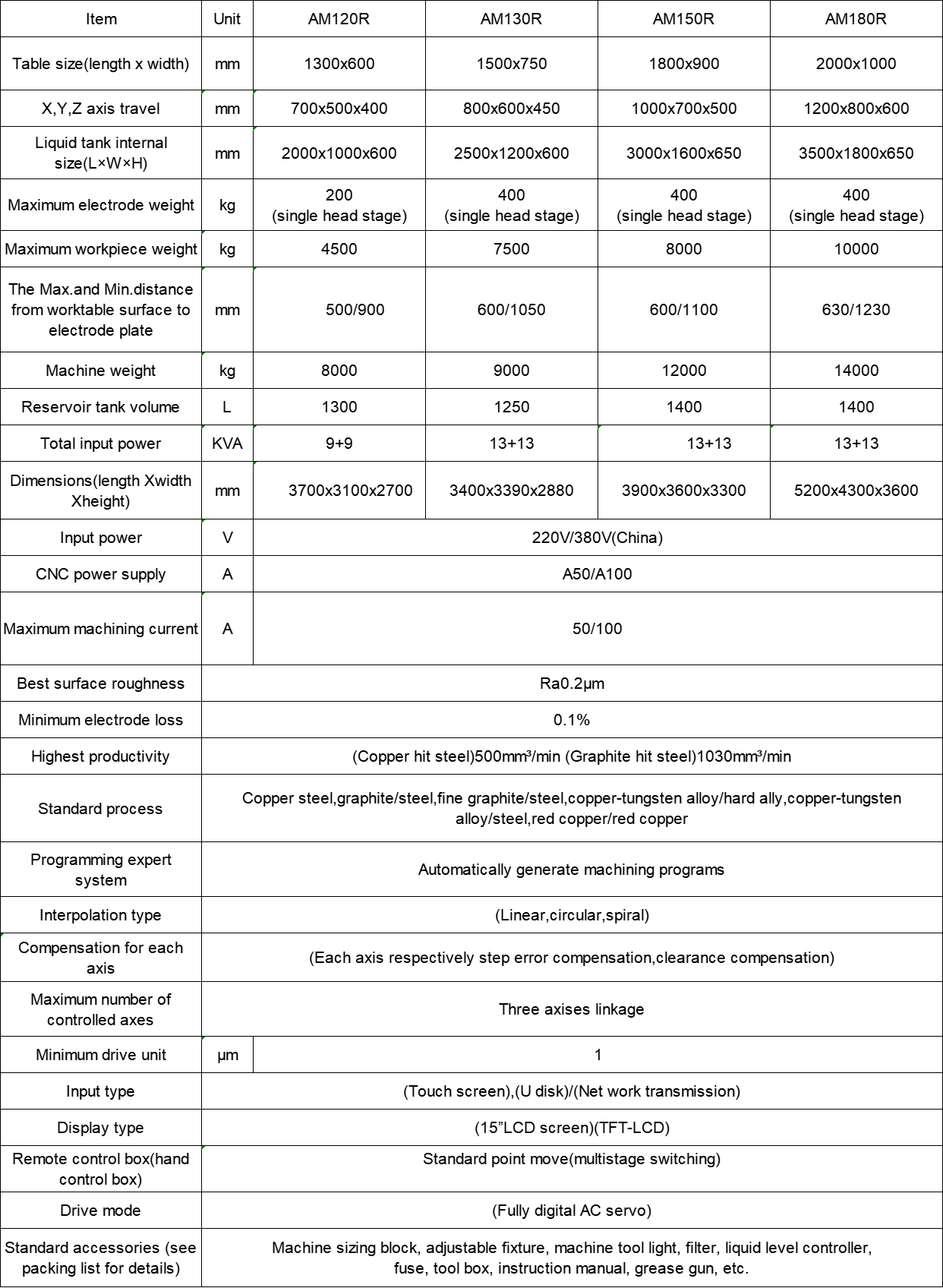

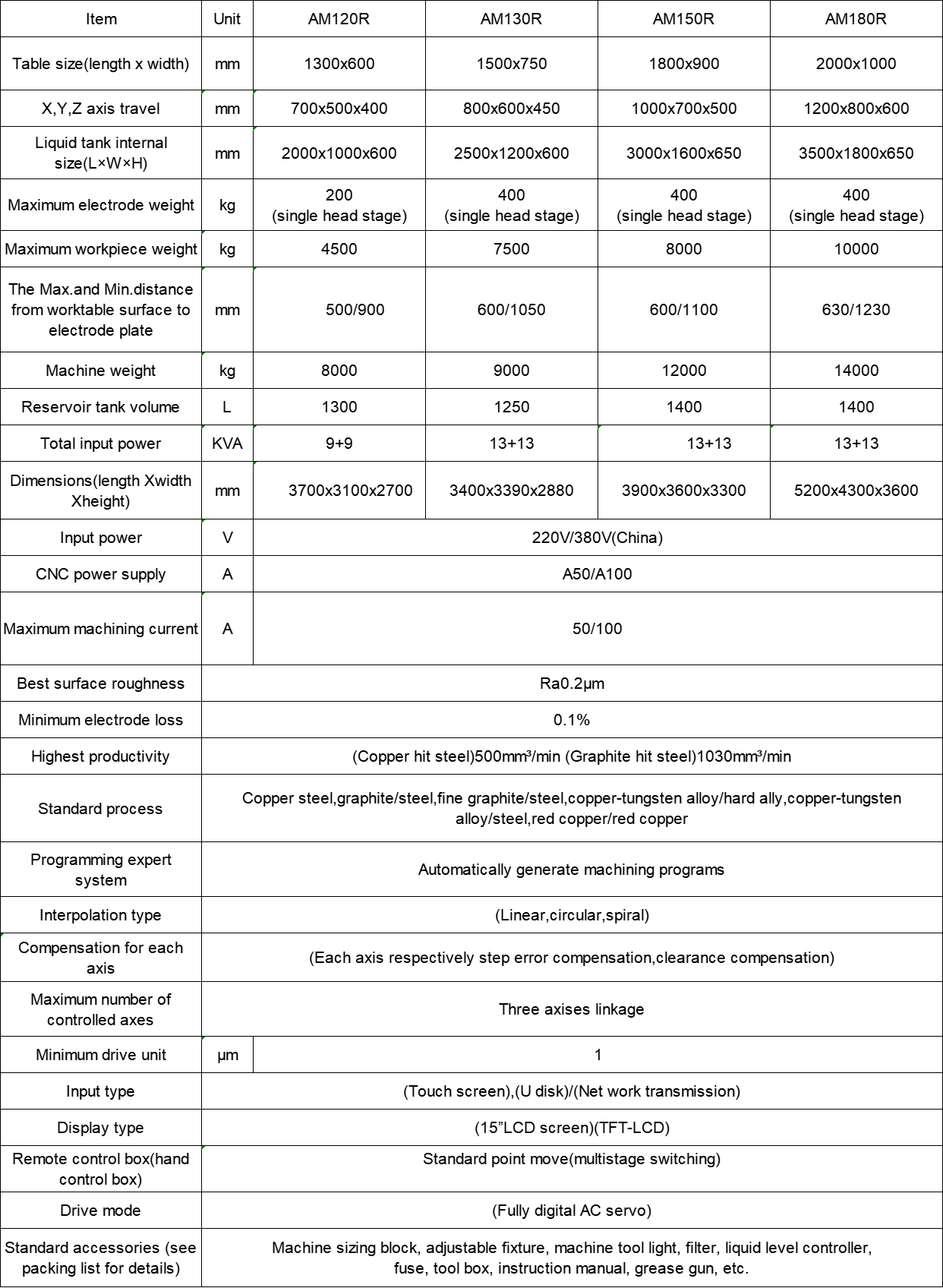

Parameter

Key Features:

Dual CNC EDM Heads: Enable parallel processing or different tasks, doubling productivity.

Windows-Based Control System: User-friendly interface supporting network connectivity and data integration for IoT-ready manufacturing.

Automatic Tool Changer (ATC): Supports multi-electrode setups with seamless switching for complex geometries.

3D On-Machine Inspection: Reduces setup time and ensures dimensional accuracy without secondary measuring.

Oil Tank Auto-Lift System: Enhances operational convenience and maintenance efficiency.

Adaptive Power Supply Technology: Optimizes discharge parameters for different materials and geometries.

Mirror Surface Finish Capability: Achieves surface roughness as low as Ra ≤ 0.1μm.

Energy-Saving Operation: Reduces power consumption and operational costs.

Advantages:

High Efficiency: Dual-head design cuts machining time by up to 50%.

Superior Precision: Repeatability within ±2μm, ideal for micro-molding and aerospace components.

Ease of Use: Intuitive Windows OS with remote monitoring and file transfer capabilities.

Low Maintenance: Designed for durability with easy-access components and self-diagnosis functions.

Customizable Options: Available with various tank sizes, electrode changers, and software packages.

Global Service Support: Mirrordick provides lifelong technical support and software upgrades.

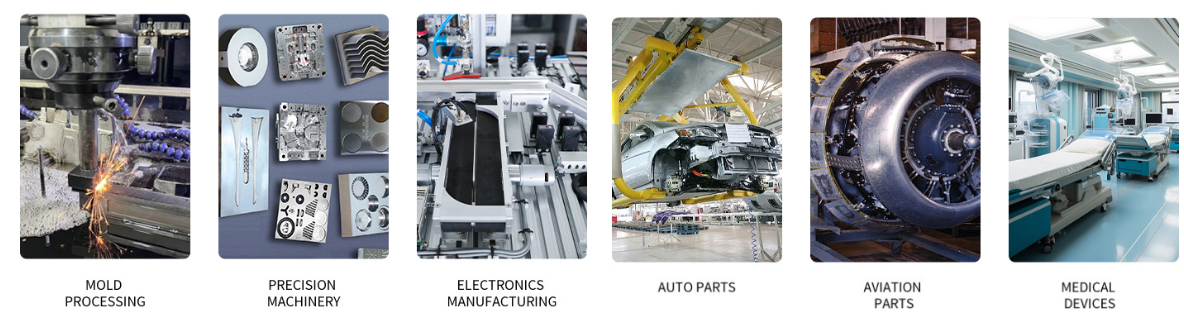

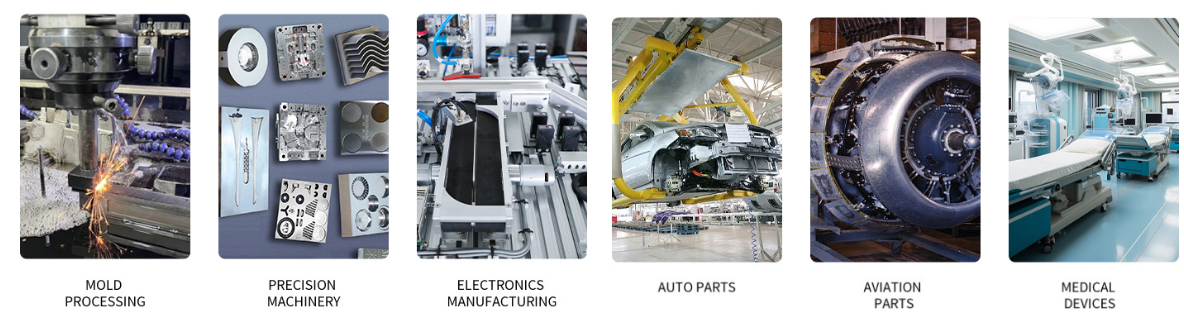

Application Industries:

Mold & Die Making: Injection molds, stamping dies, precision forging dies.

Medical Devices: Surgical instruments, implant components, micro-medical parts.

Aerospace: Turbine blades, engine components, fuel system parts.

Automotive: Gear molds, sensor components, high-precision fixtures.

Electronics: Micro-connectors, semiconductor packaging tools.

Energy: Components for turbines, fuel cells, and cooling systems.

FAQ Section:

Q1: What is the maximum workpiece weight supported by the AM150R?

A: The standard table load capacity is 1500kg, but custom solutions are available.

Q2: Can the machine run unattended?

A: Yes, with the ATC and 3D inspection system, it supports fully automated overnight operation.

Q3: What kind of surface finish can be achieved?

A: Under optimal conditions, Ra ≤ 0.1μm is achievable.

Q4: Is training provided for new users?

A: Yes, we offer online and on-site training along with detailed documentation.

Q5: Do you provide software updates?

A: Yes, all Mirrordick machines come with lifelong free software upgrades.

Q6: What materials can be processed?

A: Any conductive material including steel, carbide, titanium, copper, and superalloys.

Phone

Phone